Kee Klamp® Technical Specifications - The Kee Klamp Fitting

The simple but effective engineering principle of the Kee Klamp® fitting is the foundation of the most versatile pipe connection system available. There are many variations of fittings to suit a wide range of applications, providing the versatility to achieve virtually any structural configuration.

Kee Klamp fittings are generally made from cast iron* and manufactured to the requirements of European Standard (EN) 1562 and EN 1563. Available to suit eight pipe sizes, Kee Klamp provides a wide range of fittings. A simple hexagon key is the only tool required to create a strong, rigid joint. A recessed grub screw tightened by the hexagon key firmly locks the pipe into the fitting. The grub screw is generally manufactured in case-hardened steel* and benefits from Kee Koat® protection against corrosion. This combined with the ThreadKoat® (patented) factory-applied coating for the threaded recesses ensures that Kee Klamp fittings achieve longer life and better corrosion resistance.

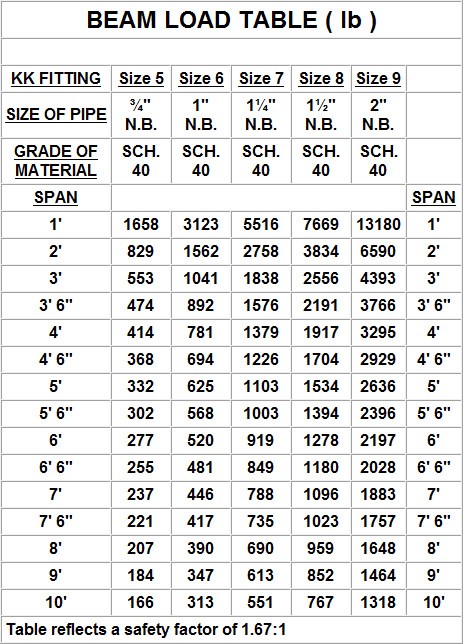

A Kee Klamp fitting (size 5 to 9) can support an axial load of *2000 lb (900 kg). per grub screw with the grub screw tightened to a torque of 29 lb. ft.(39 Nm).

* Materials used can vary according to application. Please refer to the manufacturer for detailed specifications.

Specifying Kee Klamp Fittings

The information on fittings is comprehensive because of the coding system we have adopted, making it easy to use.

Diagrams are shown for each fitting showing entry of the pipe, a table of dimensions and a definition of use adjacent to its appropriate Type number (10, 15, 20, 25, etc.).

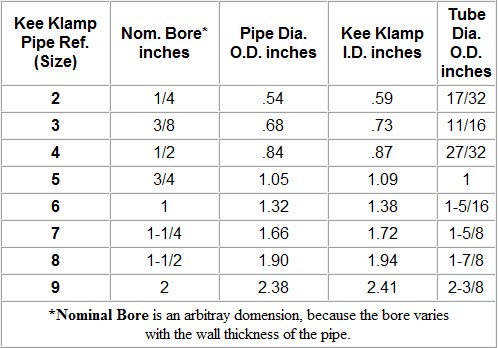

Alongside the Type number is a code (4, 5, 6, 7, etc.) relating to the outside diameter of the pipe for which the Kee Klamp fitting had been designed. The relationship between the Kee Klamp pipe reference and standard pipe outside diameter is explained in the chart.

Example: (1) A 10-7 is a Type 10 Kee Klamp fitting with both sockets designed to accept a pipe that has an outside diameter of 42.4mm or 1 11/16″ (1 1/4″ Nominal pipe Size). (2) A 25-9 is a Type 25 Kee Klamp fitting with all three sockets designed to accept a pipe that has an outside diameter of 60.9mm or 2 3/8″ (2″ N.P.S.).

Where more than one pipe reference is shown alongside a particular Type number, it indicates that the individual sockets are designed to accept different sizes of pipe. In a multi-digit code number, the first figure relates to the ‘A’ socket and the second to the ‘B’ socket. Example (3) A 45-76 is a Type 45 Kee Klamp fitting with ‘A’ socket accepting a pipe that has an outside diameter of 42.4mm or 1 11/16″, and a ‘B’ socket accepting a pipe/pipe that has an outside diameter of 33.7mm or 1 11/32″.

Kee Industrial Products can give general guidance relating to the use of each Kee Klamp fitting. The nature of the product means that the ultimate responsibility for selecting the correct fitting for an application lies with the customer.

The customer should also ensure that the existing structure to which the Kee Klamp construction is being secured is of sufficient strength to support both the self-weight of the Kee Klamp construction and the imposed loads applied, including wind loads, snow loads and any other superimposed loads.

Metric Beam Load Table

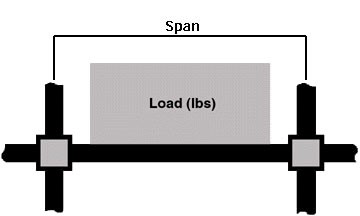

For uneven load distributions or single spans, the required pipe size must be determined by standard bending moment calculations assuming a Kee Klamp joint to give a simply supported beam. The table shown below gives an indication only of the safe load uniformly distributed, in kg, that may be carried per shelf consisting of front and back pipes when used as continuous beams. Recommended set screw torque: 39 Nm.

At loads greater than 900 kg, consideration must be given to the grub screw slip.

Metric Upright Load Table

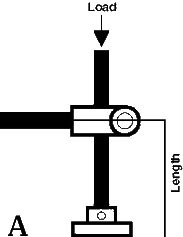

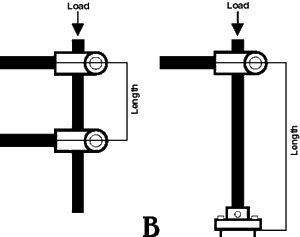

This table gives an indication only of the safe load, in kg., that may be carried between the above restraints by single pipes to BS 1387 when used as uprights. Loads listed under ‘A’ columns refer to those loads that are obtainable according to schematic ‘A’, and loads listed under ‘B’ columns refer to those loads that are obtainable according to schematic ‘B’. Schematic ‘B’ details a racking system that is mechanically affixed to the surface on which it stands whereas schematic ‘A’ details a free-standing racking system. Recommended set screw torque: 39 Nm.

Vibration Test Report

Test Report: Vibration of Kee Klamp Assemblies

Exhaustive tests on samples of standard size 7 Kee Klamp fittings were performed by an independent research laboratory. The purpose of the test was to evaluate the use of either standard set screws or self-locking set screws.

Test Arrangement

A “Tee” section test assembly was made using three 300mm lengths of galvanized 1 ¼” standard pipe held together by a socket Tee fitting (Type 25-7). The vertical leg of the test assembly was supported in a standard railing flange (Type 62-7). The completed assembly was then rigidly attached to the vibration table.

The test assembly was initially assembled using standard grub screws and tested in the configuration. The standard grub screws were then replaced with self-locking grub screws and the tests were repeated.

Test Procedure

The test was conducted on a Ling 667 kg Electromagnetic vibration table.

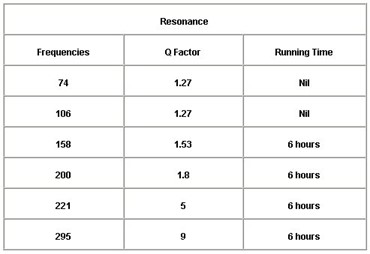

The table was programmed to perform a resonance search between 25 and 350 Hz. The following table details the resonant frequencies that were recorded.

During the resonance search amplification factors, Q, were measured at each resonant frequency—the point of reference being the end of one horizontal pipe. The table was then held at one of the resonant frequencies, set in motion with a controlled acceleration level of 4g, and run for a period of six hours. This was repeated for three more resonant frequencies in descending order of the “Q” factor.

During the 24 hours of vibration at the four resonant frequencies above no signs of loosening with either type of set screw occurred.

View component availability on our e-commerce site. For more information contact us.