The Evolution of Installing Glass Railing Systems

Glass provides versatility in architectural design by creating open, airy spaces. Glass railing systems have become a popular choice for both interior and exterior applications. This railing feature offers unobstructed views while ensuring safety and durability.

Glass railing infills present a sleek, modern design that perfectly aligns with contemporary architectural trends. These infills allow natural light to flow freely into spaces, enhancing biophilic design principles. Designers and builders appreciate how glass railing systems allow sightlines and contribute to a sense of openness.

Additionally, glass railing systems align with the growing emphasis on sustainability. Manufacturers often use recyclable materials to create the glass, contributing to LEED credits and supporting green building certifications.

Simplifying the installation process for glass railing systems is essential to fully realizing their benefits. Traditional wet glaze methods have long posed challenges for glass railing installations. Innovations such as dry glaze glass systems, advanced locking mechanisms and lightweight materials have revolutionized the installation process.

f951f6d7-c573-46c2-ab7f-59a4e51269c5.jpg?Status=Master&sfvrsn=f7377a16_5)

Early Beginnings: Traditional Wet Glaze Methods

Architects and builders did not always consider glass railing systems among their primary options. Traditionally, installers used a wet glaze method to install these railing systems. This process involved mixing cement fillers to hold the glass panels in place.

Installers closely monitored the curing process and reapplied the filler as necessary, ensuring proper adherence. This was both time-consuming and labor-intensive. Additionally, installers had to weld all connection points, followed by grinding, polishing and buffing. These steps made glass panel installation complex and required specialized training and tools.

Older glass railing systems traditionally utilized materials such as carbon steel or cast iron. Moving these cumbersome pieces around job sites, especially upstairs or across long distances, posed significant challenges for installers. The heavy weight of these components further complicated the installation process, making it less efficient and more labor-intensive.

Drawbacks to traditional wet glaze methods still exist even after the installation is complete. Over time, the sealant can deteriorate, requiring regular maintenance to prevent moisture intrusion. Additionally, in cases of shattered glass or damage, the glass replacement process is labor-intensive and requires careful preparation. New sealant applications can delay project timelines with longer curing times.

These factors highlight the intricate challenges and consistent maintenance needs that come with wet glaze installations. Repair services are essential in extending the lifespan of these systems. The installation process needed improvement to keep glass a viable railing option.

The Rise of Dry Glaze Installation

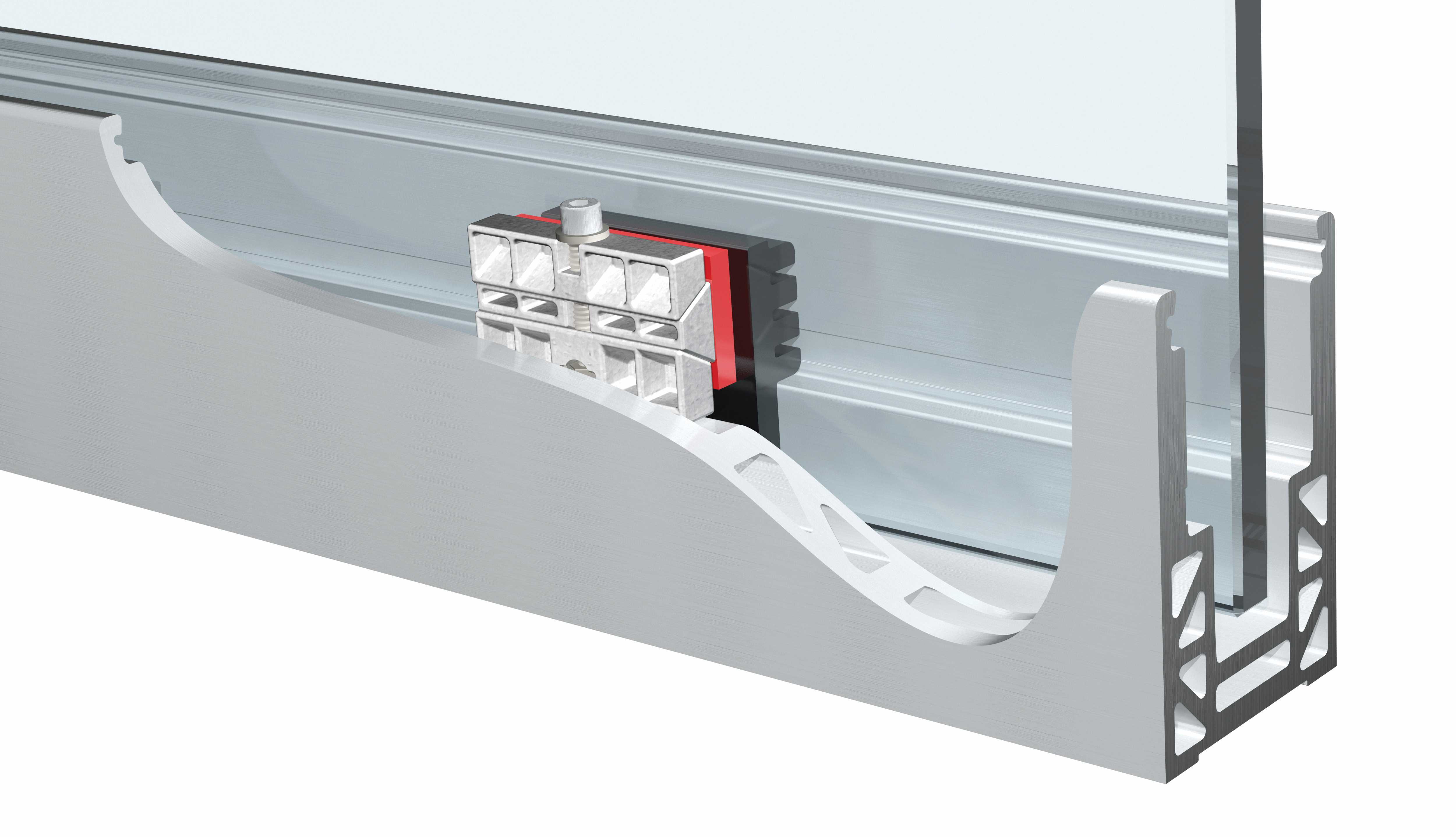

Innovators in glass railing systems developed a dry glaze method to overcome the challenges of wet glaze installations. Unlike traditional wet glaze, dry glaze uses advanced locking mechanisms within the base shoe to secure the glass panels.

This method eliminates the need for cement fillers and curing periods, enabling a faster and more straightforward installation. It reduces labor costs and facilitates easier adjustments, which were challenging with wet glaze glass installation.

Additionally, designers have recognized the need for lighter materials. Modern glass railing systems now feature extruded aluminum base shoe moulding, which is easier to transport and install. The dry glaze method is user-friendly and requires minimal training

Beyond convenience, dry glaze systems secure glass panels more firmly and enhance safe installation. The base shoe moulding system is a modular component, designed for easy assembly and disassembly. This modularity speeds up installation and ensures seamless integration, making it practical and efficient for construction projects.

Innovative Dry Glaze Solutions

Wagner's PanelGrip® exemplifies a dry glaze method that significantly streamlines glass installation. The dry glaze glass shoe moulding system features robust locking mechanisms and a lightweight design. It allows a single installer to quickly assemble it without special tools or fillers.

The extruded aluminum base provides a secure, structural foundation for glass rails. The design of the base shoe moulding installation offers various anchor portions for various substrates. Additionally, the design supports structural glass to meet the demanding requirements of a guardrail.

The innovative base shoe moulding qualifies for LEED credits. PanelGrip's no-post system maximizes light transmission for complete transparency and creates a brighter, more appealing environment. The PanelGrip system is customizable to meet the needs of architects, glaziers, general contractors and fabricators.

Level Lock Plus™ is another example of a system developed by Wagner that uses the dry glaze glass technique. Level Lock Plus technology allows users to tilt the glass two degrees backward or forward for perfect alignment. This ensures precise positioning and helps the glass adjust to weather changes, reducing the risk of shattering.

The Level Lock Plus locking mechanism technology is user-friendly and requires no special training or preparation. The shoe cradle holds the locking mechanisms, which tighten from one side only. This intuitive design installs up to 70% faster than other leading dry glaze shoe moulding railing systems. After leveling the glass and securely locking the mechanisms, the system conceals all fixtures with a cladding panel.

This system consists of extruded aluminum, which provides a low-maintenance solution and unparalleled durability. Wagner offers numerous cladding options to help customers achieve their design vision. Choose from satin-finished aluminum, rust-resistant stainless steel, or black anodized cladding for a modern look.

Conclusion

Glass railing installations have seen significant advancements, moving from traditional wet glaze methods to modern dry glaze systems. Modern methods like Wagner's PanelGrip® and Level Lock Plus reduce labor costs and expedite project timelines.

With robust locking mechanisms and lightweight designs, dry glaze systems secure glass panels firmly and enhance safety. Their modular components simplify installation and support sustainable practices, creating brighter and more appealing spaces.

As demand increases sleek and eco-friendly designs, glass continues to be a prominent choice for modern architectural projects. The evolution of glass railing systems shows how innovation and smart design work together. These solutions meet the changing needs of the built environment.