Wagner's Commitment to Quality

Wagner is committed to continuous improvement as an employee-owned company, providing our valued customers with the highest quality products and services. We achieve this by maintaining a steadfast dedication to delivering value through:

Advanced Quality Planning Activities

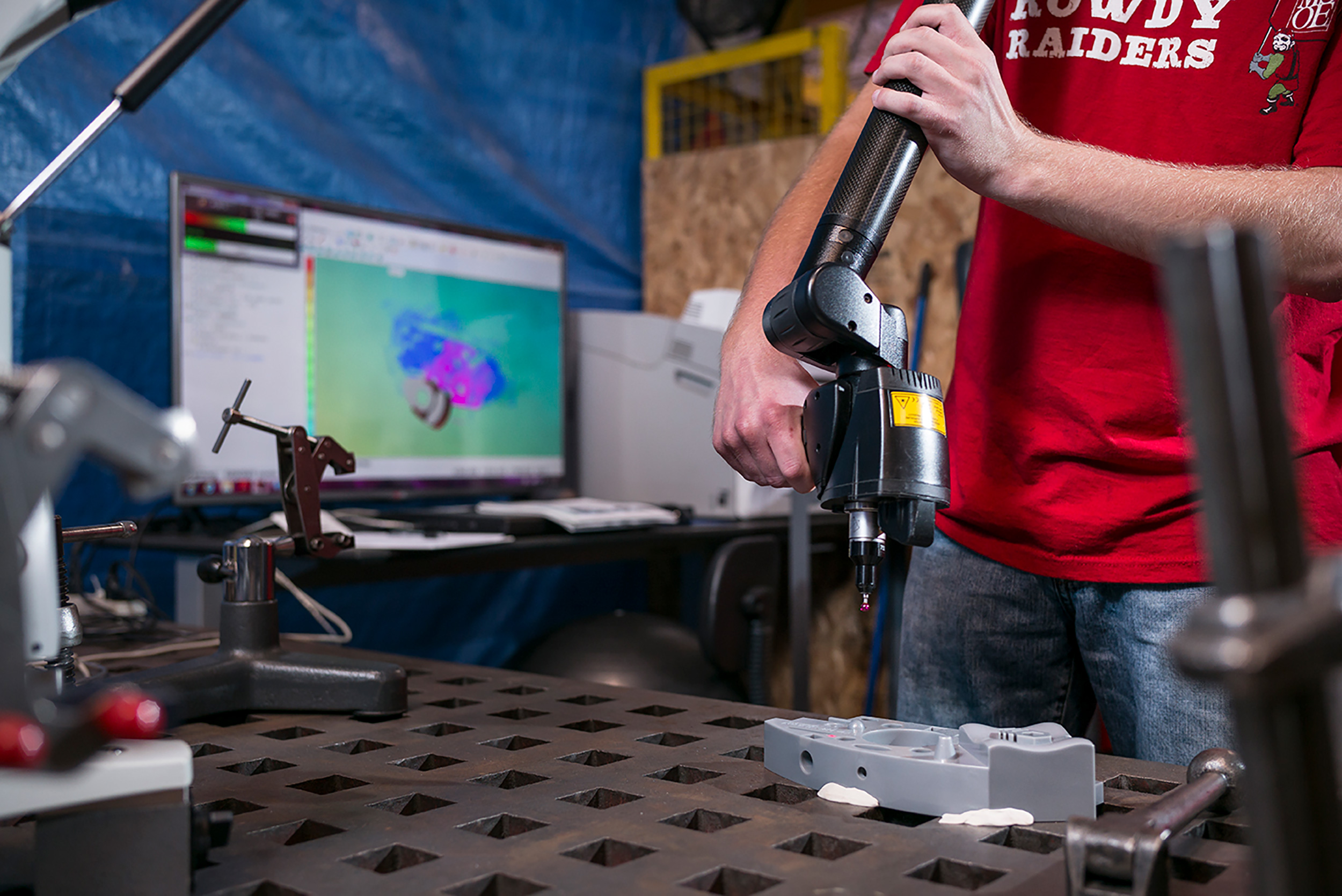

Our equipment and technicians deliver unparalleled quality and consistently perform at the highest level possible.

Process Innovation

Our in-house quality engineering staff uses tools to ensure parts are made to specification and processes remain stable.

Team-Based Continuous Improvement

Wagner uses state-of-the-art fabrication equipment to deliver the finest quality metal parts to our customers.

Quality is Top of Mind so You Can Have Peace of Mind

As a leading railing manufacturer, we understand our customers expect the highest quality in the products and services they receive from Wagner. To maintain this standard, we employ top-tier programs, machinery and personnel to ensure consistent quality in our parts and products before they leave our facility. To provide peace of mind when working with Wagner, we ensure:

- Quality personnel hold Six Sigma certifications.

- Hexagon Metrology is conducted by trained and certified Romer operators.

- GD&T qualifications are met, ensuring proper layout capabilities.

- Laser templates are used for verification.

Tube Bending Efficiency

Wagner eliminates guesswork and material waste from the tube bending process while reducing production time. This is achieved by measuring a prototype tube, sending the design to a qualified bender, and automatically calculating the bend corrections needed to ensure consistent, identical sections.

The Romer PC-DMIS portable system enhances operational monitoring by providing advanced algorithms and best-fit, iterative techniques. This system enables precise measurement of complex, contoured parts, improving efficiency and effectiveness.