Holes and Notches in Tempered Glass

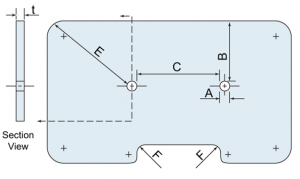

Holes and notches in tempered glass should be located within specified areas per this image. Refer to the table for noted dimensions.

Glass Edge to Hole Rim: The minimum distance from the rim of a hole to the nearest edge of the glass must be ¼” or 2 x glass thickness, whichever is greater. Tolerance for the location of the hole from the specified edge is ±1/16”.

Minimum Distance Between Holes: The minimum distance between the rims of adjacent holes must be 3/8” or 2 x glass thickness, whichever is greater. Tolerance for dimension between hole centers is ± 1/16”.

Glass Corners to Nearest Rim of Hole: Holes in the vicinity of a corner must be positioned so that the nearest edge of the hole is a minimum distance from the corner of 6.5 x the glass thickness.

Hole Dimensions: The minimum dimension of a hole should be at least 1/16″ larger than the thickness of the glass. The maximum dimension of the hole should not be more than 1/3” at the narrowest dimension of the piece.

Notches and Cutouts: All must have a fillet with a radius equal to, or greater than the thickness of the glass.

Use this table for reference with the image above.

| (t) Glass Thickness | 1⁄4″ | 3⁄8″ | 1⁄2″ | 3⁄4″ |

|---|---|---|---|---|

| (A) The minimum diameter of holes | 5⁄16″ | 7⁄16″ | 9⁄16″ | 1-3⁄16″ |

| (B) Distance from edge of the hole to the edge of the glass | 1⁄2″ | 3⁄4″ | 1″ | 1-1⁄2″ |

| (C) The distance between rims of holes | 1⁄2″ | 3⁄4″ | 1″ | 1-1⁄2″ |

| (E) Distance from corner to the rim of holes | 1-5⁄8″ | 2-7⁄16″ | 3-1⁄4″ | 4-7⁄8″ |

| (F) Minimum fillet radius | 1⁄4″ | 3⁄8″ | 1⁄2″ | 3⁄4″ |

All fabrication that penetrates the glass surface (i.e., holes, notches, cutting) must take place prior to tempering or heat strengthening. Attempting fabrication on tempered glass WILL cause it to shatter.

Glass fabrication must be done before the glass is tempered.

For more information contact us.