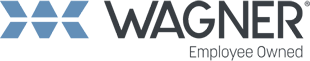

Swaged vs. Swageless Cable Fittings

Which Is Right for Your Project?

In the world of cable railing systems, choosing the right fittings is crucial for ensuring both functionality and aesthetics. The industry predominantly uses two types of fittings: swaged and swageless. Swaged fittings provide strength and security, making them perfect for high-tension applications, while swageless fittings offer convenience and easy installation without specialized tools.

Each type offers unique benefits and suits different applications. Understanding the differences between these fittings helps ensure the right choice for your project.

Swaged Cable Fittings

Installing swaged cable fittings typically requires a hydraulic press or similar equipment. This process creates a secure, permanent connection by tightly compressing the fitting onto the cable end. Here are some key points about swaged cable fittings:

Strength and Security

Swaged fittings offer a secure connection, ideal for high-tension applications where safety is paramount. The swaging process tightly grips the cable, preventing any movement or loosening over time.

Durability

The swaging process creates a robust connection that withstands heavy loads and harsh environmental conditions. Swaged fittings resist moisture, temperature fluctuations and corrosive elements, making them suitable for marine and industrial applications. Swaged cable fittings maintain their structural integrity over time, ensuring long-term reliability.

Precision

Selecting the correct cable diameter is crucial for achieving a secure connection with swaged fittings. Precise measurements and exact cable lengths ensure a tight grip, maintaining the strength and integrity of the connection. Inaccurate measurements can lead to potential slippage and failure.

Equipment Required

Installing swaged fittings requires specialized equipment like hydraulic presses. Manufacturing companies produce these fittings in factories, utilizing precise machinery and expert craftsmanship.

Swageless Cable Fittings

Swageless cable fittings do not require any specialized equipment for installation. Designed for easy, on-site adjustments, these fittings offer maximum convenience. Here are some key points about swageless cable fittings:

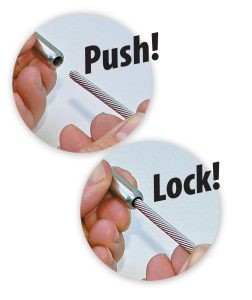

Ease of Installation

Swageless fittings offer a quick and easy installation process because they do not require specialized tools. The user-friendly design is ideal for tight deadlines and on-site adjustments. Their simple installation allows even those with limited technical expertise to achieve professional results.

Flexibility

Swageless cable fittings enable on-site adjustments, ensuring a perfect fit without precise measurements beforehand. This flexibility is particularly valuable in projects where conditions may change or where custom adjustments are necessary to accommodate unique structural requirements. Swageless fittings adapt to unexpected challenges, making them ideal for various applications.

Convenience

Their lightweight and compact design makes them easy to transport and handle, facilitating smooth and hassle-free installation. Whether used in outdoor settings, high-rise buildings or remote locations, swageless fittings offer unparalleled convenience. Their quick setup further enhances their appeal, allowing for seamless integration with minimal disruption.

Cost

Swageless fittings typically cost more upfront than swaged fittings. However, savings on equipment and installation time can offset the initial cost. Their ease of installation also minimizes the risk of errors and rework, enhancing overall cost efficiency. For cost-effective projects, swageless fittings present a compelling option that balances initial investment with practical benefits.

Choosing the Right Fitting for Your Project

When deciding between swaged and swageless cable fittings, consider the following factors:

Swaged fittings provide superior strength and security, making them ideal for high-tenson, high-load applications. In contrast, swageless fittings are ideal for projects requiring on-site adjustments or flexibility, as they allow for easy modifications.

Installation Environment

Swaged fittings are suitable when specialized equipment and a controlled installation environment are available. Swageless fittings shine in situations where portability and easy installation are crucial, providing significant advantages in diverse settings.

Budget

Take into account the total cost, including equipment and installation time. Although swageless fittings have a higher upfront cost, they can save time and labor expenses over the long term.

In conclusion, both swaged and swageless cable fittings have their unique benefits and are suitable for different applications. By knowing the strengths and limitations of each type, decision-makers can select the right fitting for their project, ensuring a successful installation.